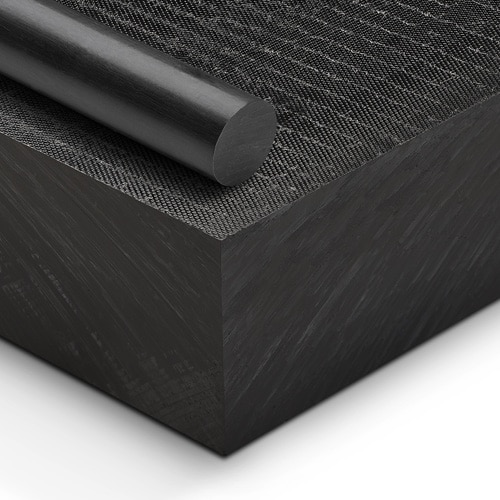

HONYPLAS®Polyethylene terephthalate (PET) Ertalyte (colours: natural white, black) is an unreinforced, semi-crystalline thermoplastic polyester based on polyethylene terephthalate (PET-P). The specific properties of Ertalyte virgin crystalline PET make it especially suitable for the manufacture of mechanical precision parts which have to sustain high loads and/or are subject to wear. PET-P Ertalyte Part Tecadur PET Sustadur PET Typical Components & Applications: Base plates Structural Gears Distribution valves Friction strips Dynamic seals Bushes Packaging machinery parts Bearing Rollers Manifolds Cases & covers Switches Insulation panes Handles Housings for appliances Ertalyte Tecadur PET Sustadur PET Component Industry Examples: Electronics Medical Automotive Mechanical engineering Food technology Ertalyte® PET-P Tecadur PET Sustadur PET Product Overview HONY Plastic MACHINING SERVICES PET-P Ertalyte Tecadur PET Sustadur PET Part : Engineering, including CAD/CAM, product and tooling design Assistance with material selection Complete precision fabricating and CNC machining services, including thermoforming, CNC milling, vacuum forming, drilling, die cutting, bending, and CNC turning Precision tolerances to +/-0.005" Sizes from small, intricate parts up to large parts Quantities from prototypes through full production runs In-process quality inspections and testing of finished parts prior to delivery Certifications to meet industry standards, including MIL specs, AMS standards, or RoHs compliance Ertalyte,PET,Sustadur PET.PET-P Ertalyte machining part,Black Ertalyte Component,PET-P Ertalyte sheet rod,Ertalyte sheet,PET-P fabriction part,PET-P,Tecadur PET Hony Engineering Plastics Limited , https://www.honyplastic.com

Here is the rewritten and improved English version of your content, with added details to make it more natural and engaging, while ensuring it exceeds 500 characters:

---

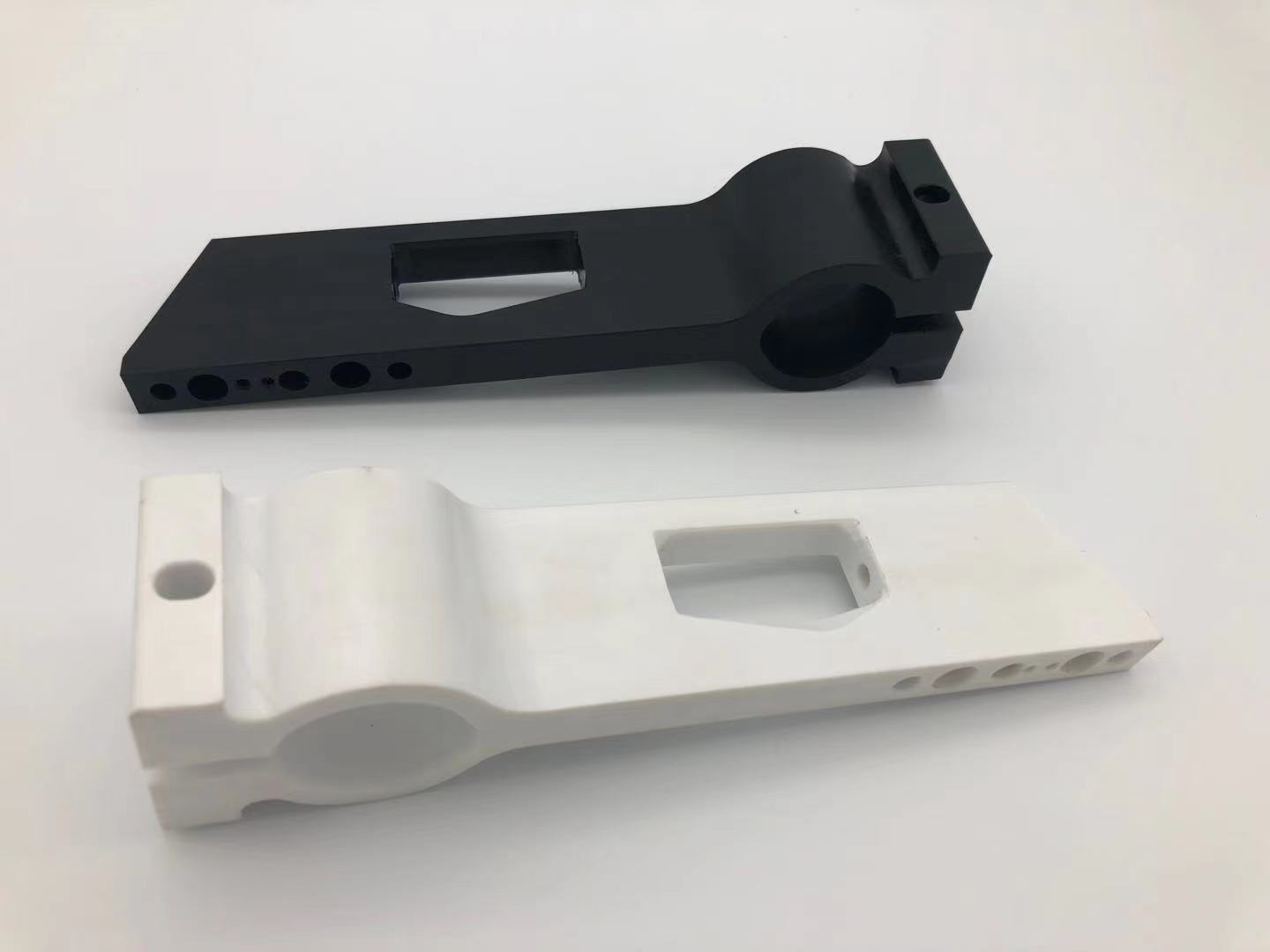

**Product Specifications:**

- **Model No.:** 13mm

- **Molding Style:** Forging

- **Application:** Power

- **Heat Treatment:** Tempering

- **Forging Tolerance:** ±0.5mm

- **Certification:** ISO 9001:2008

- **Trademark:** Goliker

- **Specification:** As per Drawing

- **Processing Object:** Metal

- **Molding Technique:** Die Forging

- **Material:** Steel

- **Surface Treatment:** Sand Blasting

- **Standard:** ASTM

- **Steel Types:** Carbon Steel, Alloy Steel

- **Transport Package:** Shipped on Pallets

- **Origin:** China

**Support Bracket**

**Trade Mark:** Goliker

**Manufacturing Process:** Hot Forging

**Material:** Carbon steel, alloy steel, and other types

**Size:** Customized according to customer drawings

**Standards:** DIN, ASTM, BS, JIS, GB, AISI, ANSI, GOST

**Heat Treatment:** Determined based on mechanical property requirements

**Machining:** Optional

**Surface Treatments Available:** Plain, Sand Blasting, Hot-Dip Galvanizing (HDG), Zinc Plating, Dacromet, Black, Paint, Powder Coating

At Goliker, we specialize in a wide range of products including container accessories, railway components, construction forgings, hardware tools, and power fittings. Our team consists of over 10 experienced engineers and technical staff, along with more than 50 skilled forging workers and managers. We are equipped with advanced production facilities, including electric screw presses ranging from 300 tons to 1,000 tons, as well as various other machinery such as horizontal lathes, CNC lathes, machining centers, drilling machines, grinders, cleaning machines, and stamping equipment. This allows us to offer comprehensive services from forging to final processing. With an annual output exceeding 10,000 tons, we have built strong relationships with numerous large enterprises both domestically and internationally.

---

Let me know if you'd like it tailored for a specific audience or platform.