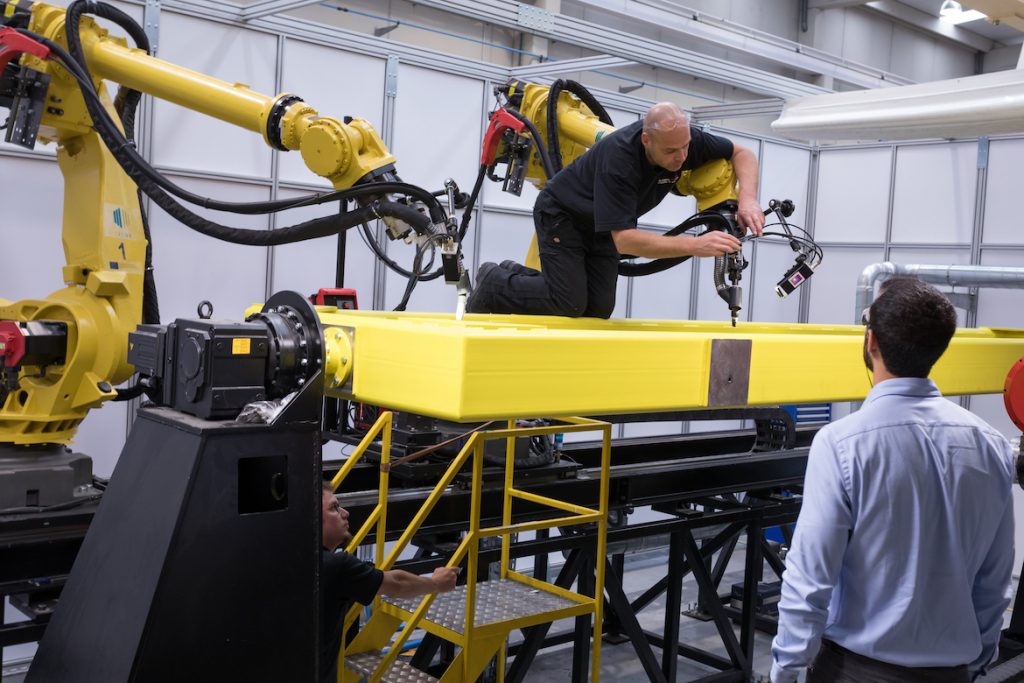

Project partner Global Robots fine-tunes one of LASIMM’s robotic arms, which is part of the massive 14m x 11m x 5m machine. Image courtesy of Loxin.

Â

The European LASIMM project brought together 10 organizations and is now ready for operation

Imagine a machine so advanced it could redefine how large-scale industrial components are built. That's exactly what the LASIMM project has achieved. This ambitious initiative, backed by the EU’s Horizon 2020 program, brings together 10 partners from six countries to create one of the world’s most sophisticated hybrid manufacturing systems. Now fully operational, LASIMM is set to revolutionize production in sectors like aerospace, construction, and energy.

Located at Loxin’s facilities in Pamplona, Spain, this 14-meter-long machine combines both additive (3D printing) and subtractive (machining) technologies into one system. It can produce metal parts as large as 6 meters by 2 meters and weighing up to 2,000 kilograms. The goal? To make large-scale manufacturing more efficient, flexible, and cost-effective—key drivers for Europe’s industrial future.

By integrating software and hardware from companies like Autodesk, along with academic and research institutions, LASIMM is not just a machine—it's a platform for innovation. The project aims to reduce time and costs by 20%, boost productivity by 15%, and provide greater flexibility in manufacturing processes. This is especially important for industries that require precision and customization at scale.

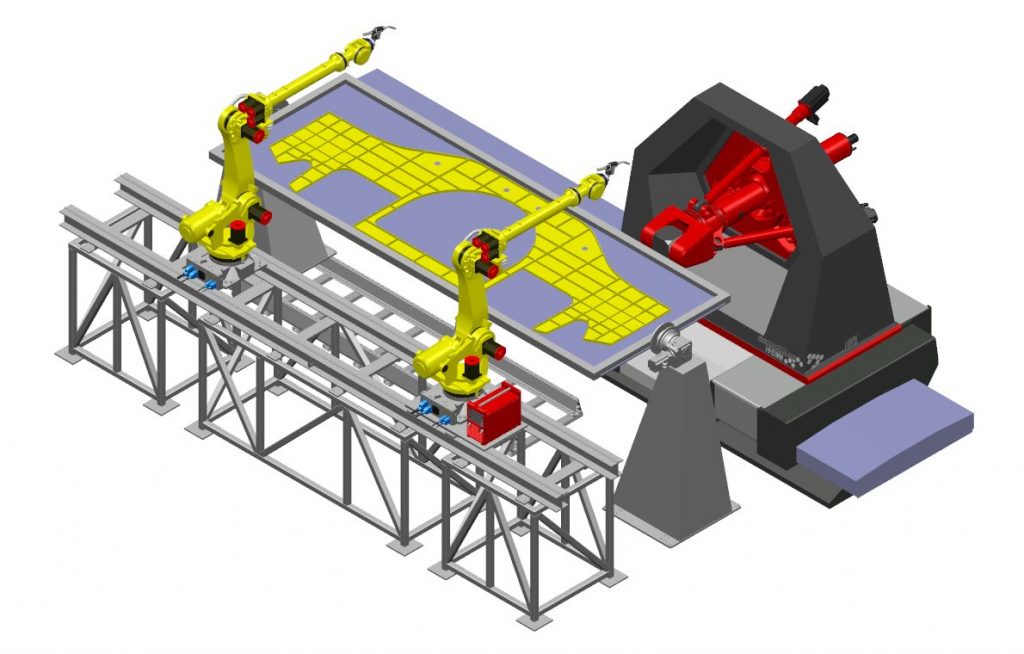

A view of the CAD design of the LASIMM in Autodesk PowerShape. Image courtesy of Loxin.

The machine features a modular setup of robotic arms and specialized milling tools, allowing it to switch between 3D printing and machining seamlessly. This versatility means it can produce complex, high-quality parts without the need for multiple machines or assembly lines. The result is faster production cycles and reduced material waste.

Learn more about Autodesk’s robot control software.

Autodesk plays a central role in the project by developing advanced software that supports multi-machine, multi-process manufacturing. Their technology enables toolpaths to be created dynamically during the build process, ensuring precision and efficiency across all stages of production.

Other key players in the project include BAE Systems, Vestas Wind Systems, Cranfield University, and several research institutes. Despite their diverse backgrounds, the team has worked closely together, even sharing meals and conversations over wine and pintxos after long days of testing and refining the machine.

Looking ahead, LASIMM represents a major step forward in hybrid manufacturing. It demonstrates that 3D printing isn’t just for small prototypes anymore—it can handle large-scale, high-volume production with the same reliability and speed as traditional methods. As the project moves into its next phase, it will begin producing real-world components, proving the potential of this groundbreaking technology.

From rendering to reality: the LASIMM project is now live and starting to manufacture large-scale parts. Image courtesy of Loxin.

“This is a game-changer,†said Eurico Assuncao, deputy director of the European Federation for Welding, Joining and Cutting and LASIMM project coordinator. “We’ve moved beyond small-scale 3D printing and entered an era where entire infrastructure components can be manufactured on demand.â€

With its ability to cut costs, reduce lead times, and support localized production, LASIMM is setting a new standard for industrial manufacturing. As the project continues to evolve, it promises to open new doors for industries looking to embrace smarter, more sustainable production methods.

Allulose is natural Non-GMO low-calorie rare sugar which made from corn starch.Allulose is a monosaccharide or simple sugar with the special function of regulating blood sugar and other beneficial to human health. It has been evaluate as the most potential sucrose substitute by the America food navigation network. It found in nature fruit such as raisins, figs and kiwis .

Allulose contains less calories than sugar, and does not appear to affect blood glucose levels, which means allulose may be a healthy substitute to sugar. Beverages is one of the leading categories exhibiting the demand for sugar substitute. Most drinks are now blended with the natural sweeteners. The health benefits and functionality associated with these sugar substitutes have led to their widespread adoption by beverage manufacturers. Consumers have also shown greater willingness to replace traditional sucrose in everyday consumables and goods with alternatives to sugar. These developments are expected to boost the penetration of allulose as a sugar substitute in beverages.

Allulose Psicose,D-Psicose,D-Allulose,D-Psicose Syrup

Shandong Bailong Chuangyuan Bio-tech Co.,Ltd , https://www.Chinabailong.com