truck mounted crane,mounted crane truck,truck with mounted crane,truck mounted crane for sale,crane lorry Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com

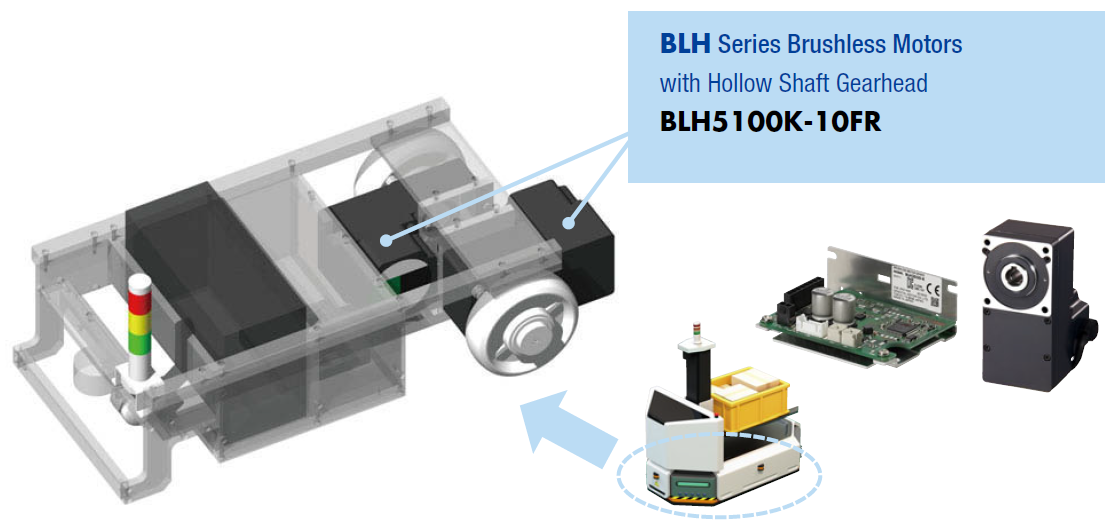

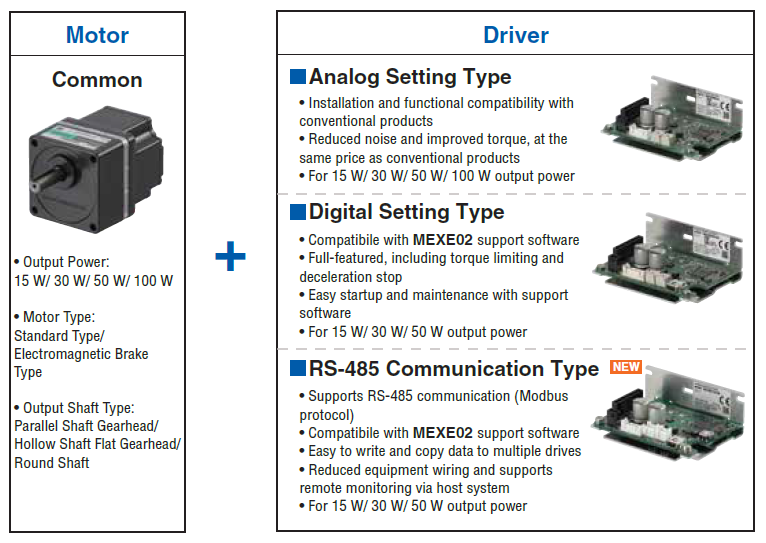

The BLH Series compact BLDC motors and drivers have been around for a while, and there’s a good reason for their popularity. Customers tend to prefer the combination of a highly efficient, compact motor and a lightweight board-type driver that’s easy to use. Additionally, the availability of a high-torque, flat-style hollow-shaft gearhead as an option helps increase torque while minimizing the footprint.

So, how do we enhance something that is already well-received? It’s actually quite straightforward: we listen to our customers and convert their complaints into new features.

Take a look at the newly redesigned BLH series brushless motor drivers below:

- **Improved Characteristics**

- **New Digital Setting Type Driver and MEXE02 Support Software**

- **Analog Setting Type vs Digital Setting Type**

- **Old vs New Compatibility**

- **RS-485 Communication Type Driver**

- **Part Number Change**

- **Download Brochure**

### Improved Characteristics

Even though there’s no design change to the motors themselves, when these new BLH Series drivers are paired with existing BLH Series motors, there’s an enhancement in torque performance across both the limited-duty range and the continuous-duty range. This increase in torque can help accelerate or decelerate the load more quickly, reducing tact times.

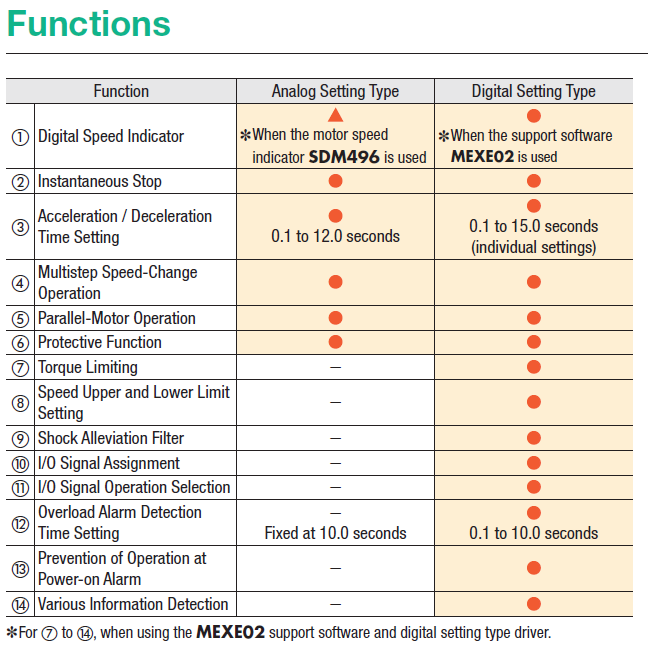

#### Extended Acceleration/Deceleration Range & New Stop Modes

With the new drivers, the acceleration/deceleration time setting range has been expanded on both ends. Furthermore, three “deceleration stop†modes have been introduced for greater flexibility in stopping the motor.

| Type of BLH Series Driver | Acceleration/Deceleration Range |

|------------------------------------|-----------------------------------|

| Older Drivers (Analog Only) | 0.5~10 seconds |

| New Analog Setting Type Drivers | 0.1~12 seconds |

| New Digital Setting Type Drivers | 0.1~15 seconds |

| Stop Mode | Description |

|----------------------------------|-----------------------------------------------------------------------------|

| Deceleration Stop 1 | The motor generates a braking force when decelerating to a stop, and operates so as to stop according to the set deceleration time setting. Regenerative power generated by the deceleration of the motor is consumed by the motor and driver and won’t return to the power supply side. |

| Deceleration Stop 2 | The motor coasts to a stop by suppressing a braking force at deceleration stop. However, if the deceleration time is shorter than the time it takes for the motor to coast to a stop, it will not be applied. |

| Deceleration Stop 3 | The motor generates a braking force when decelerating to a stop, and operates so as to stop according to the set deceleration time. The regenerative power generated by the deceleration of the motor is returned to the power supply side. |

**Why did we do this?** For instance, in applications like driving mechanisms for AGVs and AMRs, back EMF generated by back-driving of motors is a significant issue. Using Deceleration Stop 1 could help eliminate power supply and driver issues due to back EMF. Using Deceleration Stop 3 could recharge the battery for the vehicle, but ensure the battery can absorb the regenerative power.

By combining a broader acceleration/deceleration time setting range with higher torque, these motors can reach target speeds more quickly and stop more rapidly. Using a longer acceleration/deceleration time helps reduce required torque, allowing the motors to drive larger inertial loads if necessary.

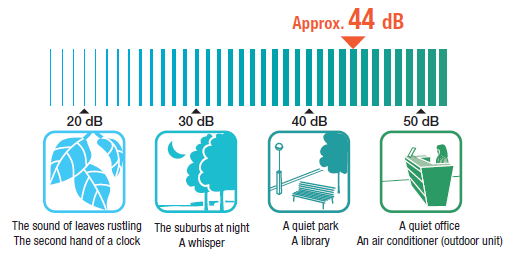

### Lower Noise

Another great improvement of the updated BLH Series drivers is reduced overall noise. These drivers utilize the sinusoidal drive method, resulting in reduced torque ripple and smoother rotation even at low speeds. As a result, the motor's drive noise is decreased by 13 dB.

---

### Digital Setting Type Driver and MEXE02 Support Software

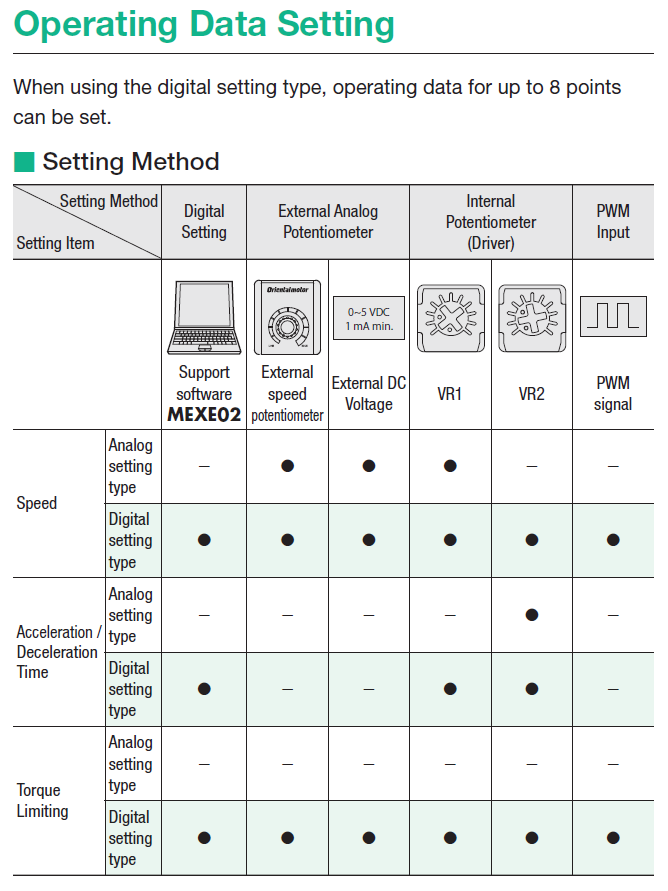

The older BLH Series drivers were considered analog setting type drivers. Analog setting type drivers allow the speed(s) to be set by an analog voltage signal, which can be provided by an internal potentiometer, an external potentiometer, or a 0~5VDC external signal.

The digital setting type driver is a brand-new driver introduced with the updated BLH Series and includes more features and functions to enhance overall performance and ease of use.

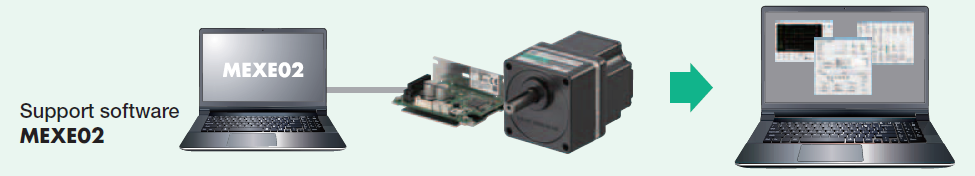

#### MEXE02 Support Software Functions

One major design change was adding a **USB connector** on the driver board and introducing a **data setting function** via the GUI. The reason I mention this first is because many of the new features and functions are due to this software, which is used to program the stored data in the driver.

Since we’re now “digitally†setting the data instead of relying on an analog signal that can be affected by varying resistance of cables, the speed regulation has improved from ±0.5% to ±0.2% (maximum speed fluctuation). This can help improve synchronous operations with multiple motors.

With the software, **8 speed data sets** are now available. With the older analog setting drivers, only 2 speeds could be set with either an internal potentiometer/external potentiometer or an internal potentiometer/external DC voltage. With digital speed setting, the speed range is also slightly widened on the low end (100~3,000 RPM vs 80~3,000 RPM), opening up the BLH Series for more low-speed applications.

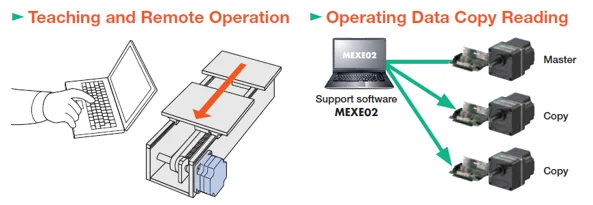

With the MEXE02 support software, I/O signal assignments, torque limiting, teaching operation, and remote monitoring are now possible, similar to our other products that use the same software.

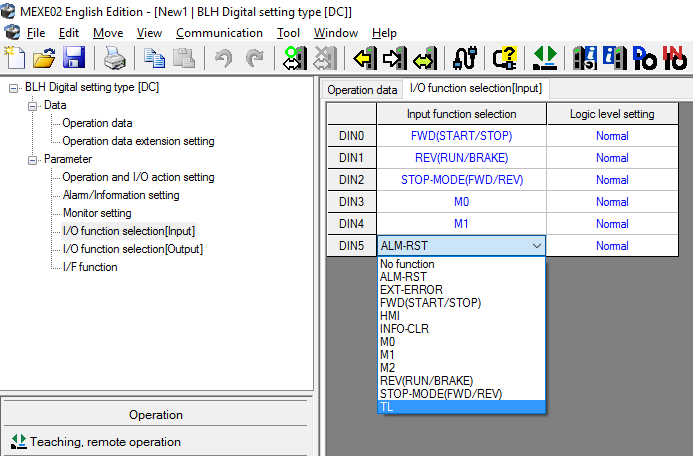

#### I/O Signal Assignments

I/O signal assignments allow the user to assign the input function they need instead of wasting an input on a function that’s not necessary. Even though you have **6 inputs and 4 outputs** physically available, there are **13 input functions and 8 output functions** you can assign.

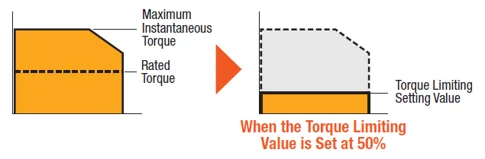

#### Torque Limiting

Torque limiting is a function to limit the motor’s torque to a percentage of the rated torque (100%) by using current and feedback.

Applications such as pressure-sensitive stamping, pressing, capping, or screwing mechanisms can benefit from this function.

#### Teaching Operation

Teaching operation allows speeds to be taught by the software’s speed toggle function. For data synchronization between multiple drivers, a data copy function is available.

#### Remote Monitoring

Remote monitoring allows real-time monitoring of system status through the MEXE02 software. Through this function, data such as speed, load factor, driver temperature, load, tripmeter, odometer, I/O status, alarm codes, and power cycles can be monitored by the software. For predictive maintenance, information bit outputs can be easily configured and connected to the host PLC.

---

### Analog Setting Type vs Digital Setting Type

Here are some comparison points showing the differences between the new analog setting type driver and the new digital type setting driver.

| Feature | Analog Setting Type Driver | Digital Setting Type Driver |

|--------------------------------------|----------------------------|-----------------------------|

| Functions | Fewer | More |

| Speed Regulation | ±0.5% | ±0.2% |

| Speed Range | 80~3,000 RPM | 100~3,000 RPM |

| Number of Speed Sets | 2 | 8 |

#### Design Change: I/O Connector

A larger I/O connector has been adopted for the new digital setting type driver. Changing from a 12-pin connector to a 14-pin connector, the digital setting type driver offers **1 more input and 2 more outputs** than the analog setting type driver, for a total of **6 inputs and 4 outputs**. Use the digital setting type driver for greater flexibility of control and better status monitoring.

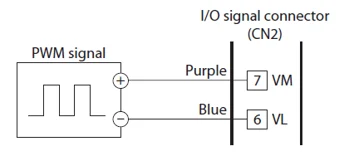

#### PWM Input

The last added feature is an input function that makes these digital setting type drivers even easier to use with host PLCs. I should mention here that all of the analog input functions (internal/external potentiometers, external DC voltage) are available with the digital setting type driver. What makes the digital setting type driver unique is its ability to accept a PWM signal from the PLC to set speed (instead of the external DC voltage). This could help eliminate the extra cost of an analog card on a PLC.

---

### Old/New Compatibility

#### Same Dimensions

The older drivers, new analog setting type driver, and new digital setting type drivers all have the same dimensions, making replacements/upgrades seamless. Since all the upgraded features and functions are on the driver, users can simply keep the same motor and replace the driver for better performance and control.

#### Same I/O Specifications

Most of the specifications are kept the same to avoid difficulties in driver upgrades. For example, we’ve kept the same C-MOS negative logic (sink) for inputs and transistor open-collector for outputs instead of sink/source photocouplers like in our other drivers, and we’ve kept the number of I/O the same (5 inputs / 2 outputs). This allows quicker replacement of older drivers without complications.

If you’re looking for more I/O, we’d suggest looking at our digital setting type drivers (6 inputs / 4 outputs).

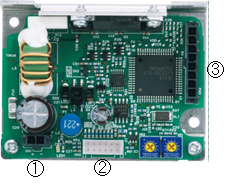

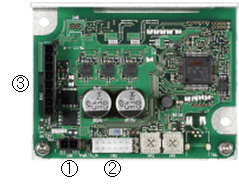

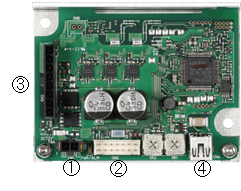

#### Motor Connector Location

Let’s take a look at the following images for comparison. Notice that for the new drivers, the motor connector is now on the left side instead of the right side. There’s a USB connector on the digital setting type drivers. Please use a USB2.0 cable to connect to your PC after installing the MEXE02 software.

| Older BLH Series Driver | New BLH Series Drivers |

|----------------------------------|----------------------------------|

| Analog Setting Type Only | Analog Setting Type |

| | Digital Setting Type |

| Older BLH Analog Setting Type Driver | BLH Analog Setting Type Driver | BLH Digital Setting Type Driver |

|---------------------------------------|--------------------------------|----------------------------------|

|  |  |  |

1. Power Connector

2. I/O Signal Connector

3. Motor Connector

4. USB Connector (for digital setting type)

---

### RS-485 Communication Type Driver

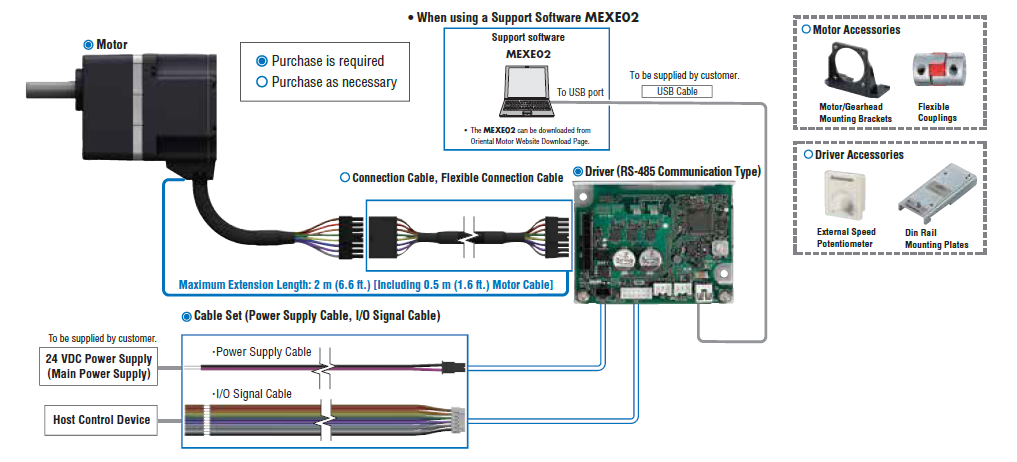

To meet monitoring or predictive maintenance requirements, or simply to reduce wiring requirements, a new RS-485 communication type driver is available. Two communication ports are added, along with MEXE02 support software compatibility. Once connected to an upper-level host controller, this driver will be able to send real-time updates on various status data. Specifications such as speed regulation and speed range will be the same as the digital setting type driver. RS-485 communication type drivers are not offered for 100W motors at this time.

---

### Part Number Change

One other major change for the updated BLH Series is how we list the part numbers. Oriental Motor has undergone a major part number change for many products to offer more product flexibility to customers. Let me explain. If you are a long-time customer, we used to offer package part numbers, which include a motor with a dedicated driver for optimal performance and guaranteed specifications. By listening to our customers’ demand for more flexibility of product combinations, we started to switch from package part numbers to individual component part numbers. This way, customers are not limited to only the package combinations that we recommend. Customers can now make up their own package using individual components, thus having more freedom to create the best combination possible for their needs.

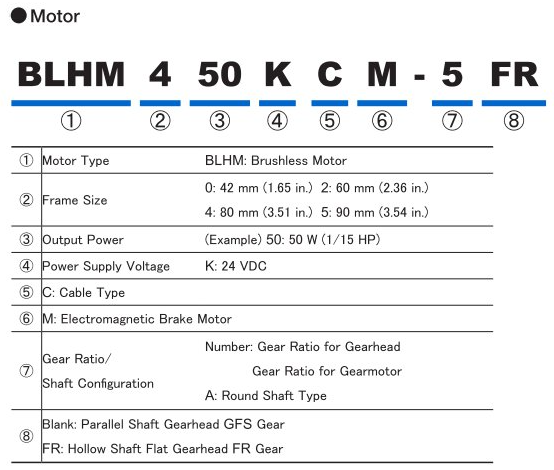

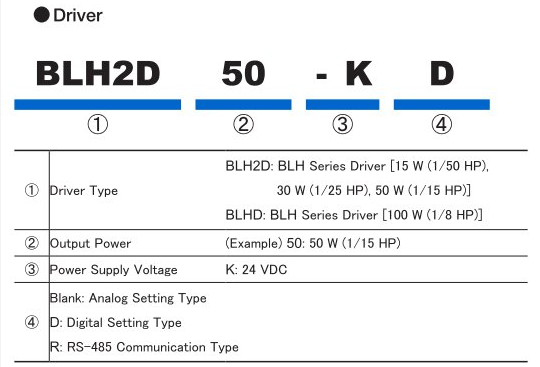

#### Part Numbers for Motor and Driver

#### Product Configuration

#### System Configuration

To make sure you are buying the right components, feel free to contact an expert.

For heavier loads or for additional AGV-specific functions, we recommend the BLV Series.

We are pleased to introduce the new redesigned **BLH Series** Drivers. Easily replace the driver to upgrade motor performance.

---

Watch the BLH Series gear motors work in an AGV!

[Video Embed]

Watch more demo videos.

---

In summary, the updated BLH Series drivers bring numerous enhancements to performance and functionality while maintaining compatibility with existing systems. Whether you need better noise reduction, enhanced torque, or advanced control options, the new BLH Series has something for everyone.

Truck mounted cranes are versatile lifting machines mounted on truck chassis, offering excellent mobility and flexibility for various lifting tasks. These cranes are essential in urban construction and logistics for their quick setup and powerful lifting capacity. Key components include Truck Crane parts like the boom truck Crane Parts and Stahl truck crane parts. For maintenance and repair, components such as ROAD ROLLER spare parts and Bulldozer Parts may be used in related machinery. Additionally, Excavator Parts and Motor Grader Parts are often integrated to enhance functionality and performance.