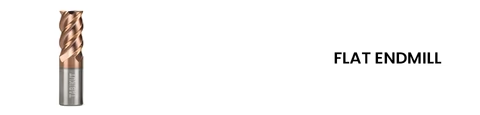

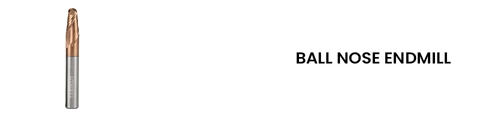

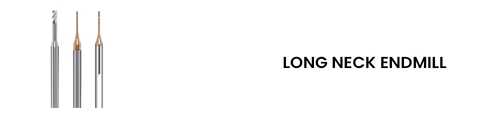

What Are Carbide Cutters? Carbide cutters are tools made from tungsten carbide, a hard and durable material known for its high resistance to wear. The raw material is typically a rod composed of tungsten carbide mixed with cobalt, which provides toughness. These rods are then precision-ground using CNC machines to create various cutter shapes, such as flat or round endmills, tailored for different machining applications. (Image - 1) The left part of Image 1 shows a raw carbide rod, while the right side displays an uncoated 3-flute flat endmill produced through grinding. Most carbide cutters are coated with specialized coatings to enhance their performance, increase wear resistance, and extend tool life. (Image - 2) Types of Carbide Cutters Flat Endmill (Image - 3) Flat endmills have a flat top surface and are commonly used in face milling, slotting, plunging, shoulder milling, and pocketing. They come in 2, 3, 4, or 6 flutes, with 4 flutes being the most widely used in industrial applications. Two-flute endmills are ideal for roughing operations on soft materials, while three-flute endmills are often used for semi-finishing on non-ferrous materials like aluminum, offering better chip evacuation. They are primarily used for finishing tasks in face and side milling operations. It's important to note that endmills are not suitable for drilling operations. Ball Nose Endmill (Image - 4) As the name suggests, ball nose endmills feature a rounded tip, making them ideal for 3D contouring, pocketing, and finishing complex surfaces. For example, a 12 mm ball nose endmill has a 6 mm radius at the tip. These tools are not designed for drilling but are excellent for creating smooth, curved surfaces on components or molds. Corner Radius Endmill (Image - 5) Corner radius endmills are similar to flat endmills but feature rounded corners, which help reduce cutting forces and distribute stress more evenly. This makes them more resistant to shock and ideal for creating radiused corners in parts. Common corner radii range from 0.5 mm to 3 mm, depending on the tool size and application. Rougher Endmill (Image - 6) Rougher endmills are designed for heavy cutting during the initial stages of machining. They are especially useful when working with difficult-to-machine materials or in deep cavities where chip evacuation is challenging. Their unique design helps break chips into smaller pieces, making it easier to remove them from the cutting area. Long Neck Endmill (Image - 7) Long neck endmills have a reduced shank body, allowing them to reach deeper areas without increasing the flute length. This design is particularly useful in tight spaces but does not increase side cutting capabilities. Three Flute Endmills (Image - 8) Three-flute endmills are commonly used for softer materials such as aluminum, brass, copper, and silver. They offer a good balance between chip evacuation and cutting performance. Some models are coated with DLC (Diamond-Like Carbon) to further improve wear resistance, although even uncoated versions are effective for similar applications. Flutes: Understanding Their Role and Usage The number of flutes on an endmill significantly affects its performance. More flutes generally mean less load per tooth, resulting in better surface finish for finishing operations. However, higher flute counts also require more feed and lower RPM to maintain tool life. Single-flute endmills are ideal for soft materials like wood, plastic, acrylic, and aluminum, especially in routers for engraving. They allow for high material removal rates. Two-flute endmills are common for semi-finishing operations on steel, stainless steel, cast iron, and non-ferrous materials, offering better chip evacuation. Three-flute endmills can be used on both ferrous and non-ferrous materials, while four-flute endmills are the most widely used in industry for steel, stainless steel, and cast iron due to their efficiency and fine finish. Five or more flutes are mainly used for very fine finishes, though they are expensive and may cause chip evacuation issues if the tool size is too large. Coatings Coatings are thin layers applied to the surface of the cutter to enhance its performance. They increase resistance to wear, heat, and abrasion, extending the tool’s life and improving cutting efficiency. Different coating types offer unique benefits, and while coatings play a crucial role, they are just one factor in determining the overall quality of a carbide cutter. We will explore this topic in more detail in our next article. changan DEEPAL parts Chongqing Zhongheng Chuangxin Auto Parts Co., Ltd , https://www.zhcx-autoparts.comSolid Carbide Endmill: A Detailed Guide to Types and Applications

changan DEEPAL parts