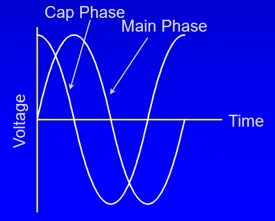

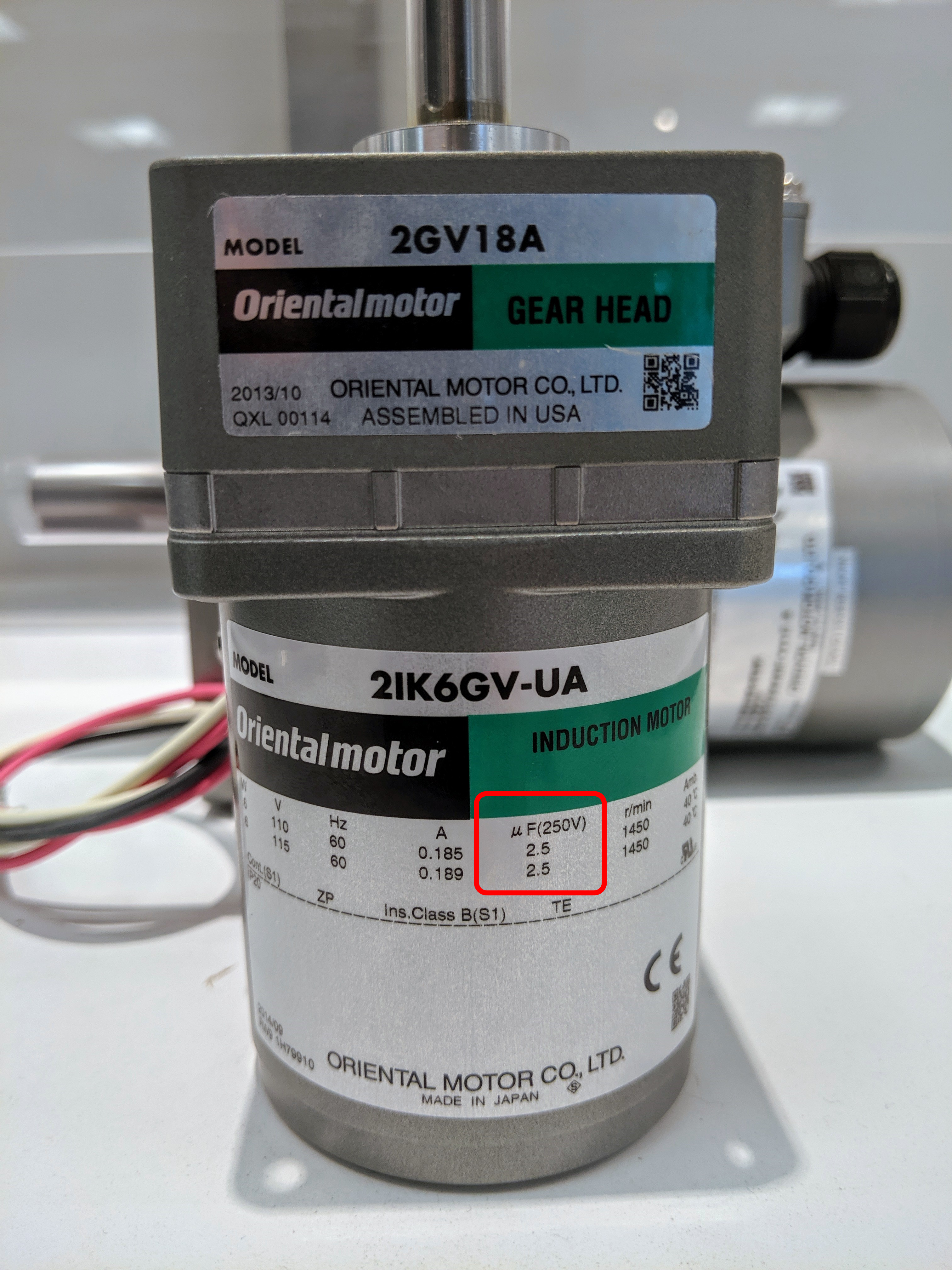

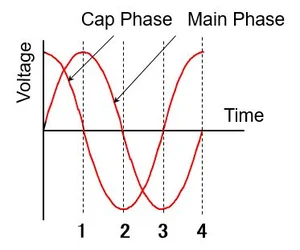

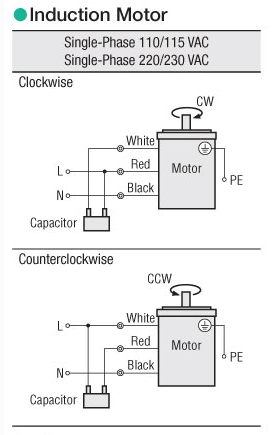

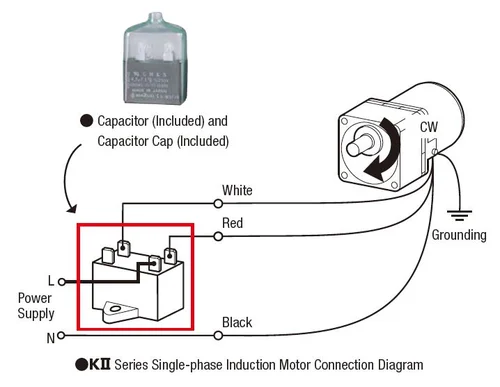

For a permanent-split capacitor type AC motor (also known as a capacitor start and run motor), a capacitor is essential for proper operation. Let's take a moment to understand why this small component plays such a vital role in the motor's performance. A Simple Experiment... To demonstrate the importance of a capacitor, let's try a simple experiment. Take a single-phase permanent-split-capacitor AC motor and connect its wires directly to a power source without using the capacitor. The motor will most likely not start unless you manually rotate the shaft. This happens because a rotating magnetic field in the stator requires at least two phases. That's where the capacitor comes into play. What Does a Capacitor Do? A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material called a dielectric. When connected to a voltage source, it accumulates charge between the plates, creating an electrostatic field. Unlike batteries, which store energy chemically and release it slowly, capacitors discharge their energy rapidly—often in seconds. A common example is the flash on your camera. The Role of the Capacitor in Motors The main purpose of the capacitor in a motor is to create a poly-phase supply from a single-phase input. This allows the motor to generate a rotating magnetic field, which is necessary for starting and running smoothly. With a capacitor, the motor can: Oriental Motor’s AC motors are all permanent-split capacitor types. They have a main winding and an auxiliary winding. The capacitor is connected in series with the auxiliary winding, causing a phase shift of 90 degrees between the two windings. This creates the illusion of a poly-phase system from a single-phase power source. What Kind of Capacitor Does Oriental Motor Use? Oriental Motor uses vapor-deposition electrode capacitors that are UL certified. These capacitors use metallized paper or plastic film as the dielectric and are also known as self-healing capacitors. Due to their compact design, they have largely replaced older paper-based models. Rated Conduction Time The rated conduction time refers to the expected lifespan of the capacitor under normal operating conditions. Typically, it is around 40,000 hours. After this time, the capacitor may fail, potentially leading to smoke or fire. It is recommended to replace the capacitor after its rated life has expired to avoid issues. Safety Features of Capacitors Some capacitors come with built-in safety features that prevent fires or explosions in case of failure. Oriental Motor’s capacitors meet UL 810 standards, having passed a 10,000 A fault current test. Capacitor Ratings and Why They Matter Capacitors are rated based on capacitance, working voltage, tolerance, leakage current, and temperature. For motor applications, the two most important ratings are capacitance and working voltage. The working voltage is usually about double the motor's rated voltage. Capacitance is measured in microfarads (μF). These values are listed on both the motor and the capacitor labels. Using the wrong capacitor can lead to increased vibration, heat, and unstable motor operation. Too much capacitance can cause overheating, while too little can reduce torque. Exceeding the rated voltage can damage the capacitor and even cause it to catch fire. Do I Need to Size the Right Capacitor for Oriental Motor's AC Motors? No. Each motor comes with a pre-sized capacitor that ensures optimal performance and efficiency. There is no need for additional sizing or adjustments. What Happens If I Use a Different Capacitor? Always use the dedicated capacitor provided with the motor. Using a different one can disrupt the phase shift needed for efficient operation, leading to overheating, inconsistent speed, or torque issues. The dedicated capacitor ensures the motor operates at its best. If the phase shift is off, the motor won’t perform efficiently, and the motor could overheat or fail prematurely. How Do I Wire a Capacitor? For a 3-wire AC motor, connect the red and white wires to opposite ends of the capacitor. The black wire connects to the neutral side of the power supply. For unidirectional operation, connect the live wire to either the red or white terminal depending on the desired direction. For bidirectional operation, use an SPDT switch to reverse the connection. Now that you understand the role of a capacitor, make sure to keep it safe and always use the correct one. If you lose it, refer to the motor label to find the right replacement. Stay tuned for more tips on motor maintenance and troubleshooting. Jacquard,Embellished Lace Fabric,Polyester Waterproof Fabric,100 Polyester Jacquard Fabric Shaoxing MingFang Textile Co., Ltd , https://www.printingsfabric.com

CAUTION: Never touch the terminals of a capacitor. Always ensure it is fully discharged before handling.