PEEK film , PEI film , Polyimide film , PC film , BOPS film, PSU film, PPSU film , PA12 film Hony Engineering Plastics Limited , https://www.honyplastic.com

If you're not making an effort to save money while using energy at home, you're essentially wasting potential savings. There are numerous benefits to using energy efficiently in your house, and the most obvious one is cost reduction. By following a few simple steps, you can significantly cut down on your electricity bills while also being more environmentally conscious. Here’s a practical checklist that will help you save money and conserve energy effectively.

**Do you have reflective coatings or window films?**

Did you know that applying window tints or films can help reduce glare and keep your home cooler during hot days? This can lower your cooling costs by up to 50%. Considering that India is one of the hottest countries in the world, this is a smart and affordable way to stay comfortable while saving energy.

**What about the paint on your walls and roof?**

Opt for light-colored paints on both the exterior walls and the roof. Lighter shades reflect sunlight, keeping your home cooler and reducing the need for air conditioning. You can also look into specialized roof coatings that not only reflect heat but also provide long-term protection against damage.

**Have you sealed your windows and doors properly?**

Air leaks can cause a significant increase in energy use. Sealing your windows and doors can save up to 30% on your energy bill. Make sure to check all gaps and cracks, especially around doors and windows, to prevent unnecessary heat loss in winter and cool air escape in summer.

**Are your appliances energy-efficient?**

When purchasing new appliances such as refrigerators, heaters, or air coolers, always check for an Energy Star rating. Appliances with 4 or 5 stars are designed to be more efficient and can help you save up to 20% on your electricity bill over time.

**Time to insulate your walls**

This is one of the most effective ways to improve energy efficiency. Without proper insulation, a large portion of your heating or cooling can escape through the walls. Experts estimate that up to 35% of energy is lost through uninsulated walls. Insulating them will help maintain a consistent temperature inside your home and reduce your overall energy consumption.

**Conclusion**

In summary, taking small steps toward energy efficiency can lead to big savings in the long run. Not only will you reduce your electricity bills, but you’ll also contribute to a more sustainable lifestyle. Another great option to consider is installing solar panels at home. Consult with a local solar provider to see if it’s a viable option for you. Our tips are easy to follow, budget-friendly, and highly effective. Take a moment to go through the checklist and start planning your energy-saving journey today.

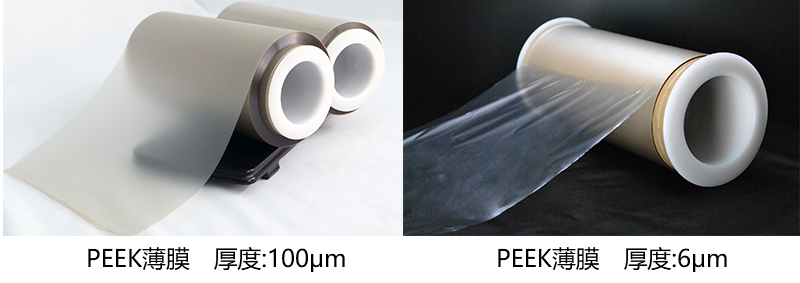

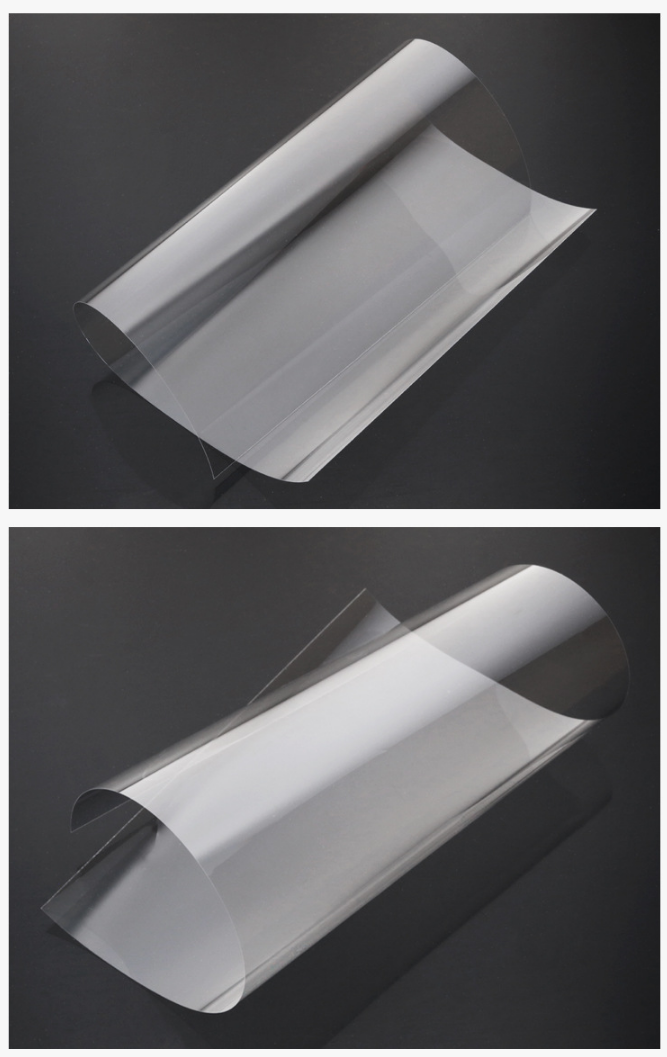

1. Low crystalline PEEK polyether ether ketone film High temperature resistant special plastic film

Polyether ether ketone (poly-ether-ether-ketone, referred to as PEEK) is a polymer consisting of a ketone bond and two ether bond repeating units in the main chain structure, which is a special polymer material. It is a special polymer material with excellent physical and chemical properties such as high temperature resistance, chemical corrosion resistance, etc. It is a kind of semi-crystalline polymer material.

PEEK film is a semi-crystalline, high-performance speciality film for a wide range of applications made from PEEK polymer, which has high temperature resistance, light weight, excellent mechanical properties and durability, excellent radiation resistance, hydrolysis resistance, chemical resistance, excellent electrical insulation and wear resistance, good barrier properties and flame retardant properties, low toxicity of the combustion products, low water absorption, halogen-free and good processing performance. Good processing performance and other characteristics.

PEEK film applications:

Electrical insulating materials, pressure sensitive tapes, printed circuit board substrates, high temperature labels, high speed motor gaskets, mobile phone hinge gaskets, soft surface heaters, aerospace insulating materials, pressure transducer diaphragms, acoustic loudspeaker diaphragms, and thermal barrier materials for lead-free soldering.

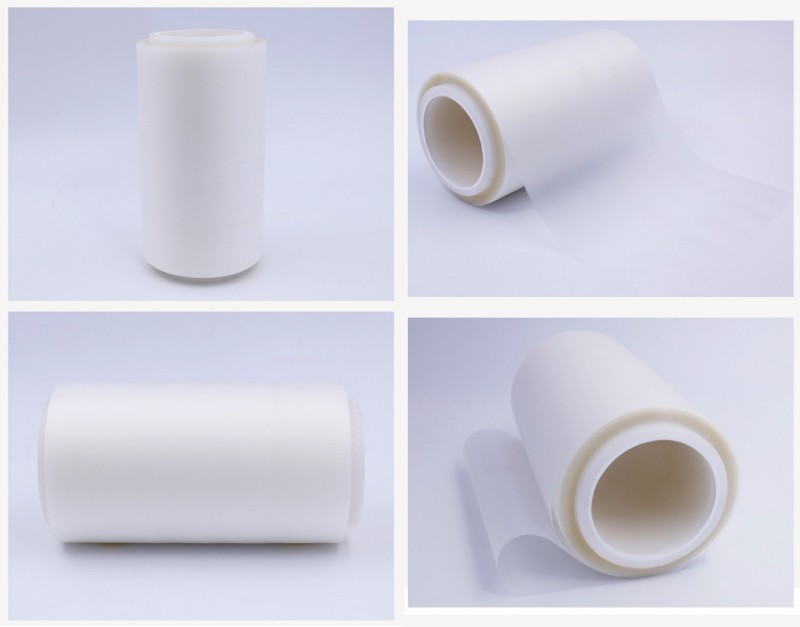

2.PA12 (poly(dodecanelimide)) film

Material PA12 Thickness: 0.05-0.8MM Length: customised Width: ≤1020 Colour: natural Surface texture: glossy/matte matt/medium sanded Melting point: 176°C MOQ 1t.

PA12 is nylon 12, also known as poly dodecalactam, poly laurolactam, is a long carbon chain nylon. Comprehensive performance is excellent, low water absorption, good low temperature resistance, good air tightness, good mechanical properties and electrical properties. With excellent mechanical properties and high durability as well as the highest possible reliability, its performance can be greatly improved by modification through chemical or physical methods. For example, through the addition of glass fibre material can be achieved after a substantial improvement in water absorption and dimensional stability, and can improve the strength and toughness of the resin.

The thermal decomposition temperature of PA12 is greater than 350°C, and the long-term use temperature is 80-90°C. The airtightness of PA12 film is good, and the water vapour transmission rate is 9g/m2.

PA12 preparation film sheet

PA12 film transparent, non-toxic, water vapour and gas (O2, N2, CO2) transmission rate is low, stored in boiling water for a year performance remains unchanged, can be used for the production of film sheet, with which to protect and package food, with the aroma of preservation, resistance to steam disinfection and the advantages of good low-temperature sex. Nylon 12 and metal adhesion is good, when bonding food, the sealing value of 100%, high peel strength.

Optical, automotive, aerospace, packaging films, sports and leisure products, cable protectors, high-end sports shoe soles, fabrics, etc.

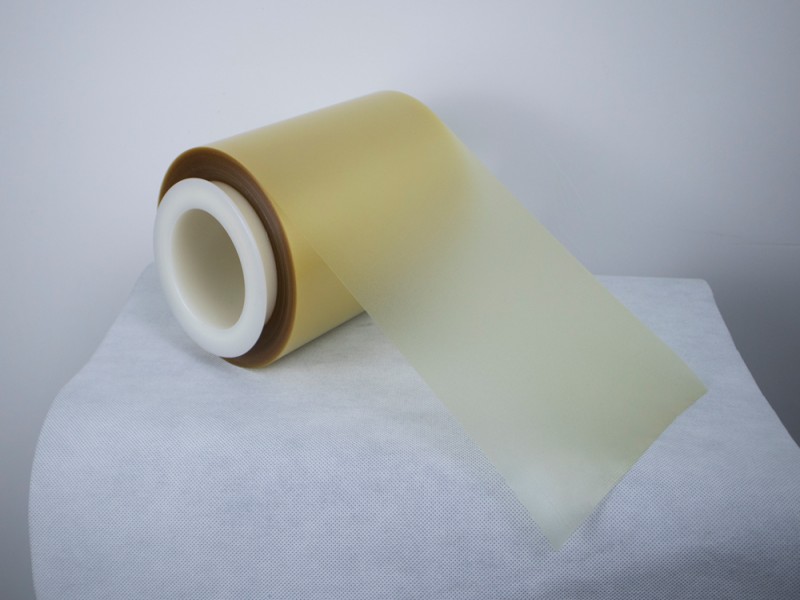

3.PEI Polyetherimide Film

Colour: natural or black Surface texture: glossy/matte, matte/medium sand Thickness: 0.025-0.5MM Width: ≤1050MM Temperature resistance: Relative temperature index 170°C

Characteristic:

Amorphous thermoplastic high temperature resistant film. (Can be used in the range of 170℃-180℃ for a long time)

Very high mechanical properties such as strength and modulus at high temperatures. Excellent dimensional stability. (Low creep sensitivity, low and uniform coefficient of thermal expansion)

Excellent insulation properties with stable dielectric constant (Dk) and low loss factor (Df) over a wide temperature and frequency range.

Excellent insulating properties, stable dielectric constant (Dk) and low loss factor (Df) over a wide range of temperatures and frequencies.

Excellent chemical resistance to most greases, detergents and disinfectants. Withstands a wide range of disinfection methods.

Penetrates visible light, infrared and microwaves.

APPLICATION OF PEI FILM

The main application of PEI film: electrical and electronic industries with special requirements such as waterproof, dustproof and breathable, speaker diaphragm, high temperature resistant supercapacitor. As well as new energy hydrogen production, green hydrogen, acid hydrogen production and so on.

4.PSU film has the following performance characteristics:

Mechanical properties:

High strength: PSU film has high tensile and flexural strength, for example, the tensile strength can still reach 60MPa at 150℃, which is better than general engineering plastics such as POM, PA and PC, etc. The mechanical properties at room temperature can be maintained at high temperatures, which is suitable for applications requiring mechanical strength.

High hardness and rigidity: The structure of PSU film contains highly conjugated diphenylsulfone and diphenylpropane groups, which gives it high rigidity and hardness, and is not easy to fracture and creep, but also has a certain degree of flexibility and toughness.

Thermal properties:

High temperature resistance: can be used in a wide range of temperatures, heat distortion temperature of up to 174 ℃, long-term use of temperature up to 160 - 190 ℃, can be used for a long time in -100 - 175 ℃, has excellent resistance to heat and oxygen aging, such as 150 ℃ by 2 years of heat and oxygen aging, the tensile yield strength and heat distortion temperature does not fall but rise, the impact strength can still keep the original value of 55%!

Low coefficient of thermal expansion: when the temperature changes, the dimensional stability is good, not easy due to thermal expansion and contraction and large deformation.

Chemical stability:

Corrosion resistance: good resistance to acids, alkalis and salt solutions, etc. It also has good resistance to detergents and hot water vapour, but it is not resistant to aromatic hydrocarbons and halogenated hydrocarbons. It can be used to manufacture parts of chemical equipment, such as pumps and valves, filters, heat exchangers, etc. It is also often used in medical devices related to repeated cleaning and disinfection.

Low ionic impurity level: PSU film has a low level of ionic impurities, which helps to maintain its performance stability in electronic and electrical applications, for example, it can be used to make printed circuit boards, capacitor film and other electrical and electronic product parts.

Electrical properties: good electrical insulation, can still maintain good electrical insulation after placed in high temperature environment, water and humid air, low dielectric constant and loss factor, but high dielectric strength and volume resistivity, and in a wide range of temperatures and frequencies (even microwave frequencies) can be maintained constant, can be used to make electrical and electronic parts, such as contactors, connectors, transformer insulation, coil bobbins and so on.

Other properties:

Dimensional stability: PSU film has good dimensional stability, small moulding shrinkage, low moisture absorption, water absorption is usually 0.2% - 0.4%, fully dry before use and prevent re-absorption of moisture, can ensure that the water content of 0.1% or less, which helps to ensure the precision and dimensional stability of the products.

Good hydrolysis resistance: in a humid environment or in contact with water, it can still maintain good performance and is not easy to hydrolysis reaction.

Transparency: PSU film is usually a semi-transparent or transparent material, presenting an amber colour with a certain degree of transparency, which can be used to manufacture products that require a transparent or semi-transparent appearance, such as certain medical devices, optical parts, etc.

Flame retardant: PSU film itself has good flame retardant, can meet certain safety requirements.

Ease of processing: PSU film is easy to process and mould, and can achieve precise tolerance, and can be moulded by injection moulding, extrusion and other common processing methods to manufacture various products.

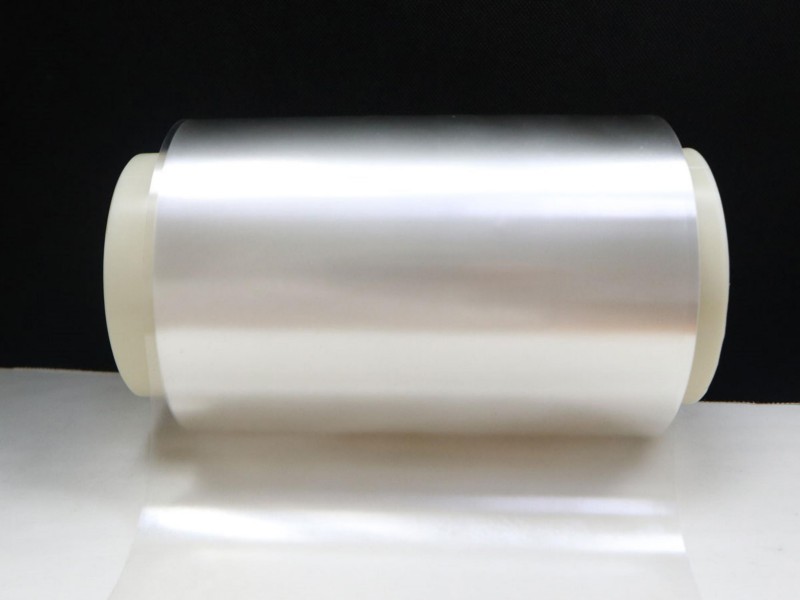

5.BOPS film (bi-oriented polystyrene film) is a polystyrene film made by bi-oriented stretching technology. It has excellent physical and chemical properties and is widely used in various packaging and industrial applications.

BOPS films have the following key properties:

High Transparency: BOPS films are highly transparent and provide clear vision.

Excellent electrical properties: its dielectric constant is stable between 2.4 and 2.7 and is virtually unaffected by frequency changes, with an angular tangent of dielectric loss of only 5 x 10^-4, the lowest of all plastic films.

Good mechanical properties: BOPS films have high tensile and impact strengths, making them suitable for a wide range of packaging needs.

Environmentally friendly: no harmful substances such as hydrogen chloride are produced during incineration and it is easy to recycle.

Production process and application areas of BOPS films

BOPS films are produced mainly through bi-directional stretching technology, which significantly improves the toughness and mechanical properties of polystyrene films, making them widely used in the packaging sector. Specific applications include:

Food packaging: Due to its non-toxicity, high transparency and good printing performance, BOPS film is commonly used in the packaging of processed food, especially fresh fruit and vegetable preservation packaging

Confectionery packaging: BOPS films are also widely used in confectionery packaging due to their high gloss and excellent twisting properties.

Defence industry and high technology: thanks to its excellent electrical and mechanical properties, BOPS film is also used in the manufacture of telecommunications equipment such as high-frequency cable insulation and variable capacitors.

6.Ultra-thin optical grade PMMA film

Polymethyl methacrylate (polymethyl methacrylate), referred to as PMMA) is a polymer, also known as acrylic, acrylic (Acrylic) or Plexiglas. It has the advantages of high transparency, low price, easy mechanical processing, etc., and is often used as a substitute material for glass.

Features

1.Has excellent weather resistance, low moisture and high light transmission, low light elasticity coefficient, good processing performance, non-toxic and excellent overall performance.

2.Acrylic protective film on the protected material has good adhesion properties, in the material handling and processing, the protective film will not buckle, fall off, now many of the protective film most of the self-adhesive or electrostatic adsorption, so that it can be very good adherence to the surface of the goods.

3.Acrylic protective film has good weather resistance and adhesion stability, after several days or long sticker peel strength growth is not significant, easy to remove, in the removal of the protected surface, there is no residual adhesive residue.

4.Acrylic protective film can have good processing adaptability, to meet the needs of deep processing of the protected object.

5.The film can be printed, can be coloured, can be pasted, outdoor exposure of long-term colour and gloss stability, excellent UV resistance.

PMMA film applications

1.PVA protective layer for polarising film.

Low moisture permeability and high transmission optical film. Solutions for different widths/thicknesses and surfaces.

2.Application in reflective materials.

Specialised PMMA reflective films for road marking and signage boards. It has excellent optical properties and weather resistance; it also provides excellent processing properties such as scratch resistance, printing and cut & paste, and meets the requirements for long-term outdoor use. DF-PMMA can be widely used in traffic signs, sign boards, safety signs, vehicles, and other areas where reflectivity is required.