Heavy Tracked Chassis,Crawler Type Coal Mine Directional Drilling Rig,Crawler Type Coal Mine Tunnel Drilling Rig,Crawler Type Metal Core Drilling Rig Ningbo Beilun Mingrui Hydraulic Equipment Co., Ltd , https://www.track-chassis.com

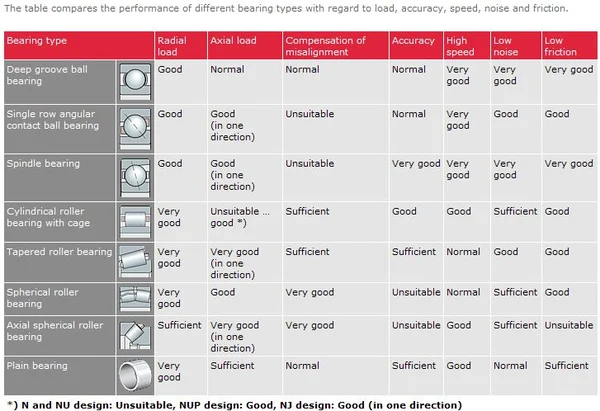

For any system that involves rotating or moving parts, selecting the right bearing and seal is crucial to ensuring performance, longevity, and safety. Bearings play a key role in enabling smooth rotation and linear motion, while minimizing friction and managing the stresses from radial and axial loads—preventing potential catastrophic failures.

Seals, on the other hand, serve a dual purpose: they keep lubricants inside the bearing and block out harmful contaminants that could compromise the system’s integrity. Whether you're working with small-scale devices or large industrial machinery, choosing the correct combination of bearings and seals is essential for optimal operation.

If you're looking for a bearing or seal solution but aren't familiar with the technical details, this guide will help you understand the different types available. It will explain how each type functions and where it's best applied, giving you the knowledge needed to make an informed decision.

### Anti-Friction Bearing Types

Anti-friction bearings are divided into two main categories: ball bearings and roller bearings. Ball bearings consist of solid spheres that rotate quickly and are ideal for moderate to heavy loads in applications ranging from small servo motors to large pumps and compressors. Their shaft sizes can vary from as small as 2mm up to 150mm.

Roller bearings, on the other hand, use cylindrical or tapered rolling elements to distribute load over a larger surface area, making them more suitable for high radial loads. There are several subtypes:

- **Cylindrical Roller Bearings** provide deep contact with the outer ring, distributing the load across a broader area.

- **Needle Roller Bearings** are similar to cylindrical rollers but have a longer length relative to their diameter.

- **Tapered Roller Bearings** feature a conical shape, allowing them to handle both radial and axial loads effectively.

- **Barrel Roller Bearings** come in symmetrical and asymmetrical designs, both offering self-aligning properties for improved performance in misaligned systems.

### Sealing Options

Choosing the right seal depends on the specific needs of your application. Seals prevent contamination and maintain proper lubrication, which is vital for the life and efficiency of your bearings.

- **Non-rubbing Seals** operate without direct contact, reducing friction and wear.

- **Rubbing Seals** require some level of contact pressure to function correctly.

- **Gap Seals** reduce the space between the shaft and housing to minimize leakage and intrusion.

- **Labyrinth Seals** offer a more robust sealing solution, especially in heavy-duty environments, by creating a complex path that prevents contaminants from entering.

### Bearings and Seals from Emerson Bearing

With over 50 years of expertise in ball and roller bearings, Emerson Bearing has built a strong reputation for quality and reliability. To learn more about how different bearings and seals work, and how they can benefit your application, visit the Bearings 101 section of the Emerson Bearing website.

[Watch our video guide on bearings and seals](https://www.youtube.com) to gain further insight into the importance of these components in mechanical systems.