Rubber Track Chassis,Rubber Track Chassis Engineering Drilling Rigs,Rubber Track Chassis 8T,Customized Rubber Track Chassis Ningbo Beilun Mingrui Hydraulic Equipment Co., Ltd , https://www.track-chassis.com

For any system that involves rotating or moving parts, selecting the right bearing and seal is crucial to ensuring performance, longevity, and reliability. Bearings are essential components that facilitate smooth rotation and linear motion in a wide range of mechanical and non-mechanical devices. They help reduce friction and evenly distribute the stress from radial and axial loads, preventing failure that could lead to costly downtime or damage.

In addition to bearings, seals play an equally important role by keeping lubricants inside the bearing assembly while blocking out contaminants such as dust, moisture, and other harmful particles. Choosing the correct type of seal can significantly impact the overall efficiency and lifespan of the system.

If you're looking for guidance on selecting the appropriate bearings and seals but aren't familiar with the technical terms or specifications, this guide is designed to help. It will provide an overview of the different types of bearings and seals available, explain their functions, and offer insights into which options are best suited for various applications.

### Anti-Friction Bearing Types

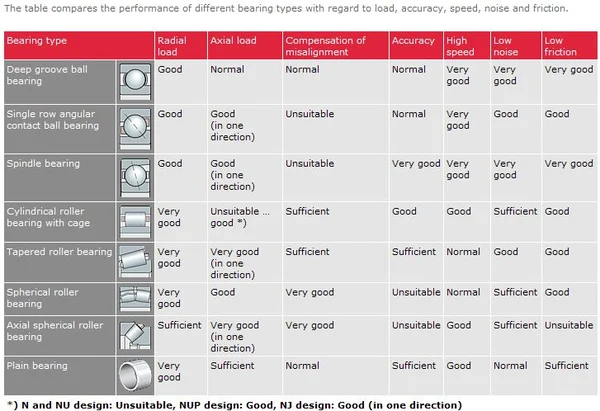

Anti-friction bearings are divided into two main categories: ball bearings and roller bearings. Roller bearings typically consist of two rings with rolling elements that move along internal tracks, making them ideal for handling heavier loads. Ball bearings, on the other hand, use solid spheres that rotate quickly and are suitable for moderate to heavy-duty applications, ranging from small servo motors to large pumps and compressors. Their shaft sizes can vary from 2mm up to 150mm.

There are several subtypes of roller bearings:

- **Cylindrical rollers** provide deeper contact with the outer ring, distributing the load over a larger surface area.

- **Needle rollers** are similar to cylindrical rollers but have a longer length and greater diameter.

- **Tapered rollers** feature a conical shape, allowing them to handle both radial and axial loads.

- **Barrel rollers** come in symmetrical and asymmetrical designs, both of which are self-aligning and help reduce misalignment issues.

### Sealing Options

Seals are critical in maintaining the integrity of the bearing system. The choice of seal depends on the specific application and environmental conditions. Here are some common types:

- **Non-rubbing seals** operate without direct contact, minimizing friction and reducing wear.

- **Rubbing seals** require a certain level of contact pressure to function effectively.

- **Gap seals** are used to reduce the space between the shaft and housing, offering basic protection.

- **Labyrinth seals** are more robust and are ideal for heavy-duty applications, providing a tighter seal than gap seals.

### Bearings and Seals from Emerson Bearing

Emerson Bearing has been a leader in ball and roller bearing technology for over 50 years. With extensive experience and expertise, they offer a wide range of high-quality bearings and seals tailored to meet diverse industrial needs.

To learn more about how each type of bearing and seal works, and to explore their full range of products, visit the "Bearings 101" section on the Emerson Bearing website.

[Watch our video to learn more about bearings and seals](https://www.youtube.com/watch?v=example)